|

Wuhan Golden Laser Co.,ltd

|

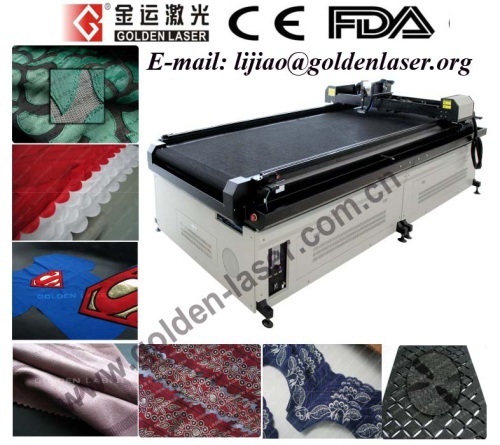

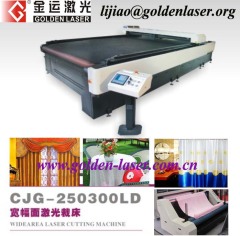

Automatic Home Textile Laser Cutting Flatbed Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Automatic Home Textile Laser Cutting Flatbed Machine

Automatic Home Textile Laser Cutting Flatbed Machine

Advantages of Laser Cutting:

1) No burr/fraying with laser cutting:

Laser cutting is done by high temperature process. It can make cut edge to close up automatically. Hence, no need to recut the patterns after one-time cutting.

2) No distortion to the processed fabric:

In the process of cutting, laser dose not touch the processed fabric, but laser beam works on the fabric.

3) High precision:

Diameter of the laser beam can be focalized into 0.1mm (we adopt top lens imported from world famous company II-VI-INFRARED).

Cutting is done exactly according to uploaded graphics through computer control.

4) High efficiency and easy operation:

Just upload the graphics into the cutting machine and laser will cut fabric into shapes as designed.

Golden Laser Technology Advantages:

1. Automatic edge-finding and cutting technology with optic Camera software

2. Multi-head digital movable cutting for toys industry

3. Efficient and smart nesting technology

4. Large format high speed engraving and punching technology for home textile fabrics

5. Advantage pattern digitizing technology

6. Long strip flying marking and cutting technology without splicing traces

7. Advanced solutions for genuine leather cutting

8. Super-long material continuous cutting

9. High performance of spreading, feeding and rewinding system

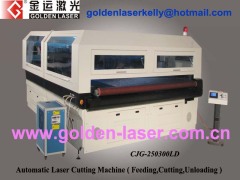

Fabric Laser cutting machine recommend model CJG-160300LD brief introduction:

1. Open-type wide area laser cutting bed. Working area of 1600mmX3000mm

2. Vacuum absorb conveyor working table with auto-feeding device, it is capable of fast and continuous cutting of textile fabrics.

3. If the length of single layout exceeded cutting area, cutting system can achieve continuous feeding and cutting.

4. Smart nesting software is optional, it can fast layout cutting graphics in the most material-saving way.

5. CNC 5-inch LCD screen operating system. Supporting multiple data transmission. Enabling offline or online operation.

6. Laser heads are synchronized with exhaust system so that can totally discharge smoke and fume from materials being cut to keep good environment and high precision of the machine.

7. You can print to the laser from a variety of programs, including CorelDraw, AutoCAD and Adobe software.

8. Equipped with optic CCD camera recognition system, it is able to automatic finding edges and cutting.

Auto Feeding Textile/Fabric/Garment Laser Cutting Machine CJG-160300LD

Garment/Textile/Fabric Laser Cutting Machine, Laser Cutting Engraving Machine, Laser Cutting System, Laser Cutting Equipment for Textile, Fabric, Garment, Leather, Shoe, Plush Toys, Label, Carpet, Rug, Mat, Automotive upholstery etc.

Laser cutting machine Application :

Suitable for cutting various flexible materials such as textile fabrics,cloth, home textile and industrial fabrics,widely used in apparel,shoes,luggage,home texitle industry.

Suitable for cutting various flexible materials such as textile fabrics,cloth, home textile and industrial fabrics,widely used in apparel,shoes,luggage,home texitle industry.

1,Non-woven fabrics for health& medical: face mask, exposure suit, insulating

clothing, bandage, sterile gauze, facial tissue, lens wiping paper, etc.

2,Home decoration cloth: Carpet, Mattress, Curtain, Doormat, Valance, Wall Cloth, Tablecloth, Bed sheet, Bedspread, Counterpane, Dust Cover, Sofa Cloth, blanket, etc.

3,Garment cloth: liner, lining, adhesive interlining, wadding piece, case-hardened cotton, synthetic leather cloth, swimwear, diving suit, spor suit, etc.

Advantages of Laser Cutting:

1) No burr/fraying with laser cutting:

Laser cutting is done by high temperature process. It can make cut edge to close up automatically. Hence, no need to recut the patterns after one-time cutting.

2) No distortion to the processed fabric:

In the process of cutting, laser dose not touch the processed fabric, but laser beam works on the fabric.

3) High precision:

Diameter of the laser beam can be focalized into 0.1mm (we adopt top lens imported from world famous company II-VI-INFRARED).

Cutting is done exactly according to uploaded graphics through computer control.

4) High efficiency and easy operation:

Just upload the graphics into the cutting machine and laser will cut fabric into shapes as designed.

Golden Laser Technology Advantages:

1. Automatic edge-finding and cutting technology with optic Camera software

2. Multi-head digital movable cutting for toys industry

3. Efficient and smart nesting technology

4. Large format high speed engraving and punching technology for home textile fabrics

5. Advantage pattern digitizing technology

6. Long strip flying marking and cutting technology without splicing traces

7. Advanced solutions for genuine leather cutting

8. Super-long material continuous cutting

9. High performance of spreading, feeding and rewinding system

Fabric Laser cutting machine recommend model CJG-160300LD brief introduction:

1. Open-type wide area laser cutting bed. Working area of 1600mmX3000mm

2. Vacuum absorb conveyor working table with auto-feeding device, it is capable of fast and continuous cutting of textile fabrics.

3. If the length of single layout exceeded cutting area, cutting system can achieve continuous feeding and cutting.

4. Smart nesting software is optional, it can fast layout cutting graphics in the most material-saving way.

5. CNC 5-inch LCD screen operating system. Supporting multiple data transmission. Enabling offline or online operation.

6. Laser heads are synchronized with exhaust system so that can totally discharge smoke and fume from materials being cut to keep good environment and high precision of the machine.

7. You can print to the laser from a variety of programs, including CorelDraw, AutoCAD and Adobe software.

8. Equipped with optic CCD camera recognition system, it is able to automatic finding edges and cutting.

Laser cutting machine Main technical parameters: | |

Laser Type | CO2 RF Metal Laser Tube |

Laser Power | 80W, 100W, 130W, 150W |

Laser Optics | Usa Ii-Vi |

Working Area | 1600mm× 3000mm |

Working Table | Vacuum absorb conveyor working table |

Cutting (no-load) Speed | 0-36000mm/min |

Repeating Location Accuracy | ± 0.5mm |

Motion System | Servo system, Safety alarm system, Embed offline control system, 5 inches LCD display |

Cooling System | Constant temperature water chiller |

Laser Power Adjustment | Following laser power adjustment |

Power Supply | AC220V ± 5% / 50Hz |

Format Support | AI, BMP, PLT, DXF, DST etc. |

Standard Collocation | Exhaust filtration systems, Mini air-compressor |

Optional Collocation | Auto feeder system, Smart nesting software |

E.m.a.i.l : lijiao(at)goldenlaser(dot)org ,

T.E.L : 00.86.189.86189.5.3.1

Related Search

Home Textile Machine

Flatbed Textile Printer

Automatic Cutting Machine

Automatic Die Cutting Machine

Automatic cable cutting machine

Laser Cutting Machine

More>>