|

Wuhan Golden Laser Co.,ltd

|

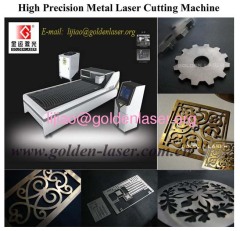

Fiber Laser Cutting Carbon Steel Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hubei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Fiber Laser Cutting Carbon Steel Machine

Fiber Laser Cutting Carbon Steel Machine

Product Name | GJMSJGGX-13090DT Fiber Laser Cutting Machine |

Applicable Material | Suits for cutting stainless steel,carbon steel,alloy steel,aluminium alloy,copper plate/coin,brass,aluminum sheet and other metal sheet/plate/pipe/tube. |

Applicable Industry | stent, stencil, gasket, solar cell, machine tools,kitchen machinery, advertisement,arts and crafts, sheet metal cutting |

Brief Introduction | FIBER Laser Cutting Machine : 300W power. (optional with 500W, 1KW, 2KW) Long lasting life time (100,000 hours) of the laser module. (IPG laser source) Specialist for thin sheet in precision Small heat affected zones create narrow cutting "kerf", have the ability to cut most complex design and create sharp corner. Dynamic focus system avoid material uneven Nesting software provides efficiency and saving. Minimized burrs and roughness Lowest maintenance cost & energy-consumption Easy operation, easy service. |

Main Technical specifications | Laser medium: IPG fiber laser Cutting area:1300*900mm/1500*3000m/600*400mm Max. cutting speed:12m/min (upto the materials) Working table: Net saw-teeth working table Cooling way: air cooling Laser wavelength:1070nm Laser output power:300W/500W Laser input power:1KW Minimum line width:<=0.1mm Cutting depth:0.2-3mm (upto the materials) Driving way: imported servo motor Transmission way: imported precision ball screw Motion System: CNC offline control Power requirements: 220V 50HZ Environment temperature: 5-35degree Continuous working time:24 hours Optional Collocation: Rotary device for pipe cutting |

Fiber Laser cutting is among the largest application for lasers in material processing. Fiber laser cutting offers an advanced alternative to conventional cutting processes. Fiber laser technology allows for smaller beam diameter therefore decreasing kerf width, decreasing heat penetration and increasing throughput. | |

Features of Fiber cutting SS | Stainless steel is fabricated across almost every industry. Conventional methods include CO2 laser cutting, plasma, water jet, sheering, punching and stamping. Cutting with a Fiber laser can eliminate almost every other method. With the speed of linear motors and the power of a Fiber laser cutting up to 1", almost every method of fabricating stainless steel becomes obsolete. Although other lasers can cut thick stainless steel, Fiber technology is extremely efficient, reliable and relatively zero maintenance. This positions Fiber laser cutting as the preferred method over conventional technologies. |

After-Sale Service | 1. One year guarantee for the whole set of machines, not including normal replacement of wearing parts. 2. 24 hours technical support by email or calling. When it is necessary, we will send technician to the customer side to solve the problem. 3. User-friendly English manual and CD for machine using and maintaining. 4. Free lifetime upgrading of self-developed English software. |

Besides Fiber laser cuting machine,we also manufacture CO2 laser cutting machine,YAG laser cutting machine,Fiber laser marking machine,laser engraving machine.Those machines are widely used in metal,nonmetal also flexible fabric. | |

Highlights of Fiber Laser Marking | Fiber Laser marking is the most flexible type of direct marking available. The ability to change various laser parameters offers the ultimate in control, quality and speed. Fiber Laser Marking Systems utilize the latest advancements in laser-based material processing. |

-- If need laser machines price,videos,specifications,pls send enquiry DIRECTLY to my mail address directly,(not on this platform site) or I can't reply you ASAP.

E.m.a.i.l : lijiao(at)goldenlaser(dot)org

M.o.b.i.l.e : 86.189.86.189.531

W.e.b.s.i.t.e : www goldenl-laser com cn

-- Notice: Pls confirm me below to help us recommend a suitable machine to you asap.

1,Which materila you need to cut or engrave?

2,What is the size and thickness?

3,What is your company and website?

4,Which country will the machine be used?

Related Search

Laser Cutting Machine

Laser Engraving Cutting Machine

Co2 Laser Cutting Machine

Laser Engraving And Cutting Machine

Laser Cutting Engraving Machine

Fiber Laser Machine

More>>